-

-

-

Company News- JINZEN at Georgia World Congress Center

Company News- JINZEN at Georgia World Congress Center -

-

-

- JINZEN Sewing Machine Spare Parts

- JINZEN Accessories

- JUKI Sewing Machine Spare Parts

- BROTHER Sewing Machine Spare Parts

- PEGASUS Sewing Machine Spare Parts

- SIRUBA Sewing Machine Spare Parts

- KANSAI Sewing Machine Spare Parts

- YAMATO Sewing Machine Spare Parts

- Kingtex Sewing Machine Spare Parts

- JACK Sewing Machine Spare Parts

- Other Brand Sewing Machine Spare Parts

- Household Sewing Machine Spare Parts

- Cutting Sewing Machine Spare Parts

- Leather Sewing Machine Spare Parts

Common Types of Industrial Sewing Machine Spare Parts and Their Functions

Industry News-In the textile and garment industry, machines must operate efficiently and consistently to meet production demands. One essential aspect of maintaining these machines involves using reliable Industrial Sewing Machine Spare Parts. These components not only ensure the continuous operation of equipment but also help improve product quality and reduce downtime. Understanding the different types of Industrial Sewing Machine Spare Parts and their specific functions is important for factory operators and maintenance teams.

Among the widely used Industrial Sewing Machine Spare Parts, needles are considered a core component. Sewing machine needles are responsible for piercing the fabric and carrying the thread through it to create a stitch. These parts come in different sizes and types, depending on the material being sewn and the nature of the operation. Regular inspection and timely replacement of needles help prevent fabric damage and maintain stitch consistency.

Another essential category of Sewing Machine Spare Parts is presser feet. These parts hold the fabric in place while the needle moves up and down during the sewing process. Different styles of presser feet are designed for specific tasks, such as zipper insertion, hemming, or creating decorative stitches. Choosing the appropriate presser foot for each sewing application improves both precision and efficiency.

Bobbin cases and bobbins are also key Industrial Sewing Machine Spare Parts. The bobbin holds the lower thread, while the bobbin case controls its tension during stitching. An uneven tension can result in irregular stitches or thread breakage. Regular maintenance of bobbin cases and using the correct bobbin size for each machine type helps maintain stable sewing quality throughout production runs.

Feed dogs are another example of Industrial Sewing Machine Spare Parts that play a crucial role in the fabric handling process. Located beneath the needle plate, feed dogs move the fabric forward or backward as the needle stitches. Worn or damaged feed dogs can cause uneven stitching and fabric slippage. Keeping these parts in good condition ensures smooth and consistent material movement.

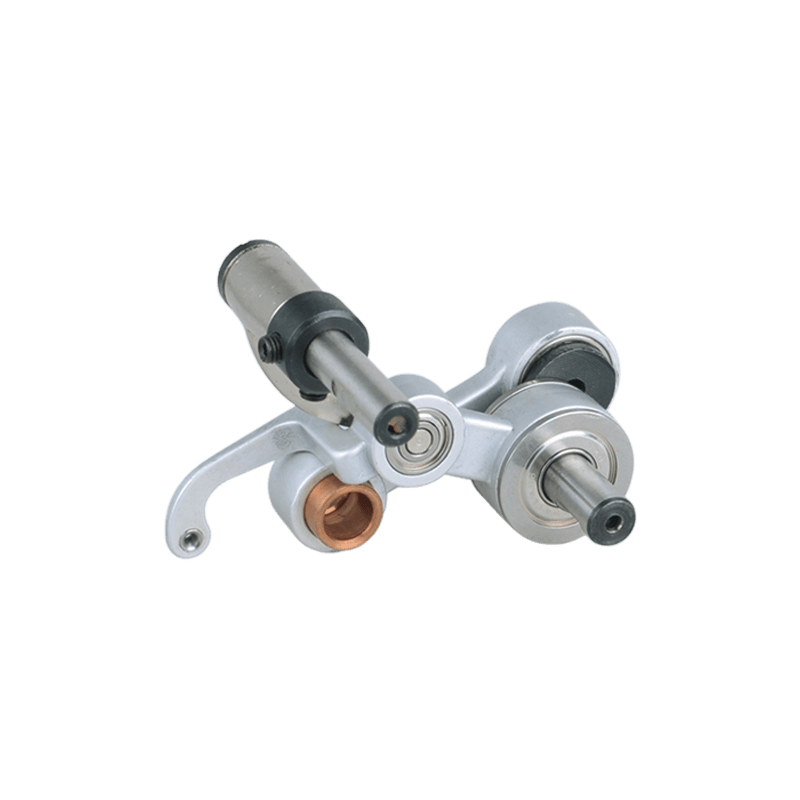

Loopers, common in overlock and chain stitch machines, are Industrial Sewing Machine Spare Parts that help form stitches by carrying the thread around the needle. Properly functioning loopers are essential for creating secure and neat seams. Misaligned or worn loopers can result in thread breakage and incomplete stitches, requiring careful adjustments and periodic replacement.

Another frequently replaced group of Sewing Machine Spare Parts includes thread guides and tension discs. Thread guides direct the thread along the correct path, while tension discs regulate thread tension. Incorrect tension can cause skipped stitches, uneven seams, or thread breakage. Regularly inspecting these parts ensures the machine produces consistent stitch quality.

Needle plates, positioned under the needle and presser foot, are important Industrial Sewing Machine Spare Parts that support the fabric during sewing. They have precisely cut slots or holes for the needle to pass through and for feed dogs to move the fabric. Damaged or misaligned needle plates can cause needle breakage and affect stitch alignment. Replacing these parts when worn is important for maintaining a smooth sewing process.

Belts and pulleys are mechanical Industrial Sewing Machine Spare Parts responsible for transferring motion from the motor to the machine’s moving components. A worn or loose belt can reduce machine speed and cause operational problems. Regular checks and timely replacement of belts ensure steady and reliable machine performance.

Tension springs are small yet important Industrial Sewing Machine Spare Parts that help regulate thread tension along with tension discs. If a tension spring loses its elasticity or breaks, it can result in unstable stitches. Replacing these springs when necessary helps maintain consistent sewing quality.

Another group of Industrial Sewing Machine Spare Parts includes oil wicks and lubricating pads. These parts distribute lubrication to various machine components to reduce wear and overheating. Regularly replacing oil wicks and ensuring proper lubrication extends the life of the machine and prevents unexpected breakdowns.

Gaskets and seals are also necessary Industrial Sewing Machine Spare Parts for preventing oil leaks and protecting machine interiors from dust and debris. A worn seal can result in oil spillage and reduced lubrication efficiency. Replacing these parts as part of routine maintenance protects machine components and ensures stable operation.

Español

Español 中文简体

中文简体 عربى

عربى