-

-

Company News- JINZEN at Georgia World Congress Center

Company News- JINZEN at Georgia World Congress Center -

-

-

-

- JINZEN Sewing Machine Spare Parts

- JINZEN Accessories

- JUKI Sewing Machine Spare Parts

- BROTHER Sewing Machine Spare Parts

- PEGASUS Sewing Machine Spare Parts

- SIRUBA Sewing Machine Spare Parts

- KANSAI Sewing Machine Spare Parts

- YAMATO Sewing Machine Spare Parts

- Kingtex Sewing Machine Spare Parts

- JACK Sewing Machine Spare Parts

- Other Brand Sewing Machine Spare Parts

- Household Sewing Machine Spare Parts

- Cutting Sewing Machine Spare Parts

- Leather Sewing Machine Spare Parts

How to Choose the Right Industrial Sewing Machine Spare Parts for Your Equipment?

Industry News-In the textile and garment manufacturing industry, the reliability of equipment is essential for maintaining consistent production. One of the critical factors in ensuring the continuous operation of sewing equipment is the proper selection of Industrial Sewing Machine Spare Parts. These components directly affect machine performance, operational stability, and product quality. Choosing the appropriate Industrial Sewing Machine Spare Parts requires careful consideration of several important aspects.

To begin with, understanding the specific model and type of sewing machine is necessary before purchasing Industrial Sewing Machine Spare Parts. Different machines require unique parts tailored to their design and operating mechanisms. For example, a high-speed overlock machine and a heavy-duty lockstitch machine will have different component demands. By identifying the correct machine specifications, businesses can ensure the selected Sewing Machine Spare Parts fit well and function effectively.

Another factor to consider is the material compatibility of Industrial Sewing Machine Spare Parts. Machines used for sewing denim, leather, or lightweight fabrics need parts that can handle different levels of tension, friction, and stitching patterns. Using spare parts made from suitable materials not only maintains stitching consistency but also extends the operational life of the sewing machine.

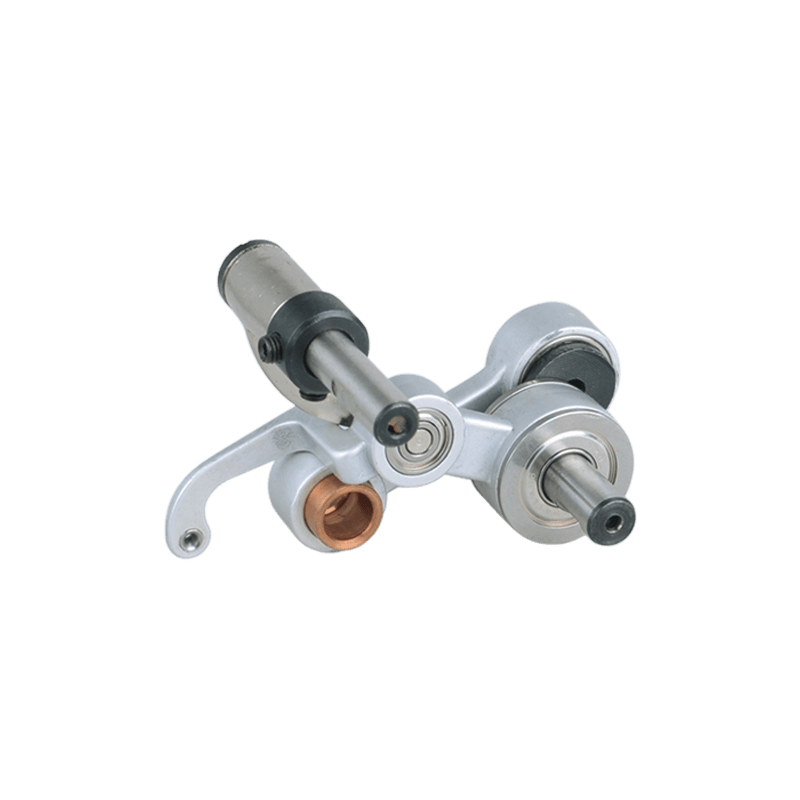

Durability and precision are also key considerations when selecting Industrial Sewing Machine Spare Parts. Since these parts are subject to continuous motion and stress, high-quality materials and accurate craftsmanship contribute to a more stable sewing process. Needle plates, feed dogs, tension assemblies, and rotary hooks should be chosen carefully to match the demands of daily production and avoid frequent replacements.

Compatibility with automation systems is another important point. Many modern sewing workshops are equipped with automated or semi-automated machinery. In such environments, it is essential that Industrial Sewing Machine Spare Parts support smooth integration with existing systems. Parts that align with computerized controls and sensors contribute to steady production efficiency and reduce unexpected breakdowns.

When evaluating Industrial Sewing Machine Spare Parts, it is helpful to consider supplier consistency and inventory availability. Choosing suppliers with a stable inventory ensures that replacement parts can be sourced quickly when needed. This prevents prolonged downtime caused by part shortages. Moreover, suppliers familiar with the specific needs of industrial sewing operations are better positioned to recommend the appropriate Sewing Machine Spare Parts.

Regular machine maintenance routines can help identify which Industrial Sewing Machine Spare Parts are prone to wear and require frequent replacement. Components such as needles, bobbins, presser feet, and loopers experience significant wear during operation. Keeping an adequate stock of these commonly replaced parts helps maintain continuous production without interruption.

Additionally, keeping up with technological advancements in Industrial Sewing Machine Spare Parts is worthwhile. As manufacturers continue to improve part designs and materials, new options often provide benefits such as reduced friction, quieter operation, or extended service life. Evaluating these improvements can help businesses optimize their sewing lines and reduce long-term maintenance costs.

In sewing production lines where large volumes and tight schedules are common, the availability of Industrial Sewing Machine Spare Parts becomes a significant operational factor. Establishing partnerships with dependable suppliers that can deliver parts promptly helps production managers respond to unexpected machine issues without compromising delivery commitments.

Training machine operators and maintenance teams about the correct use and installation of Industrial Sewing Machine Spare Parts also plays a role in equipment reliability. Proper installation techniques prevent premature wear, reduce machine vibrations, and maintain sewing accuracy.

In conclusion, selecting the appropriate Industrial Sewing Machine Spare Parts involves understanding machine specifications, material compatibility, durability, and automation requirements. By focusing on these factors, businesses can maintain stable production, reduce downtime, and extend equipment life. With a strategic approach to spare part management and reliable supplier relationships, sewing workshops can effectively support their operational goals while ensuring machine reliability and stitching consistency.

Español

Español 中文简体

中文简体 عربى

عربى